National Service Hotline:400-887-7879

THREE ADVANTAGES

Greener

Old residential buildings are dense, and odor and pollution are not easy to discharge; Yongri elevator site does not need welding, painting, pollution-free, odor-free, and more environmentally friendly;

Safer

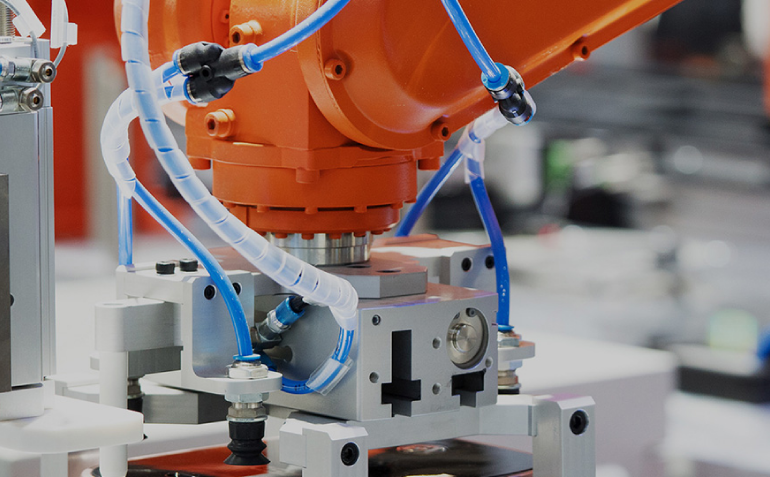

The firefighting facilities in old residential areas are not perfect, and on-site welding is prone to fire risks; Yongri Elevator is standardized in production, and the elevator steel shaft is welded by robots in the factory, which is safer without welding on site.

Fast construction

The old elevator has a narrow space, and the slow installation progress will bring a lot of inconvenience; Yongri elevator standard parts are assembled, and the on-site construction is fast, which has no impact on the owner's life.

RETROFITTING PROCESS

-

With the process

-

01

Unity of Opinion

-

02

Sign an agreement (safety inspection)

-

03

Site survey

-

04

Design

-

05

Agreement announcement (agreement and scheme)

-

06

Construction drawing review

-

07

Apply for retrofit

-

08

Joint Review

-

09

Construction to declare

-

10

Engineering construction and tracking management

-

11

Completed use (acceptance, registration, filing, handover)

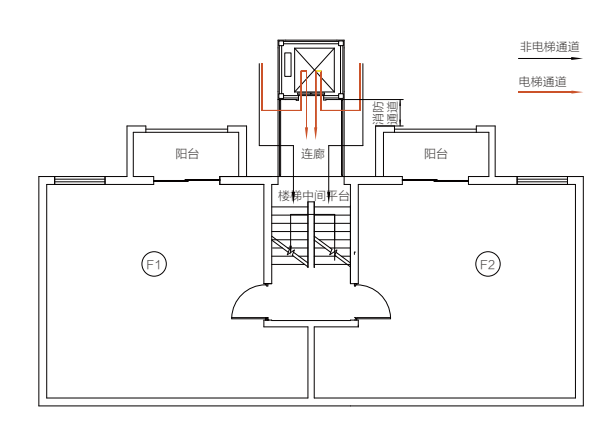

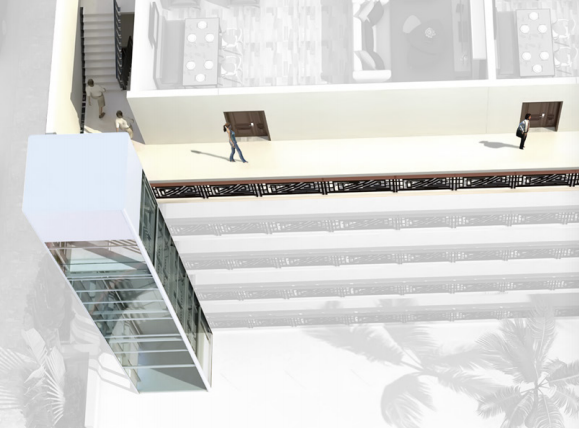

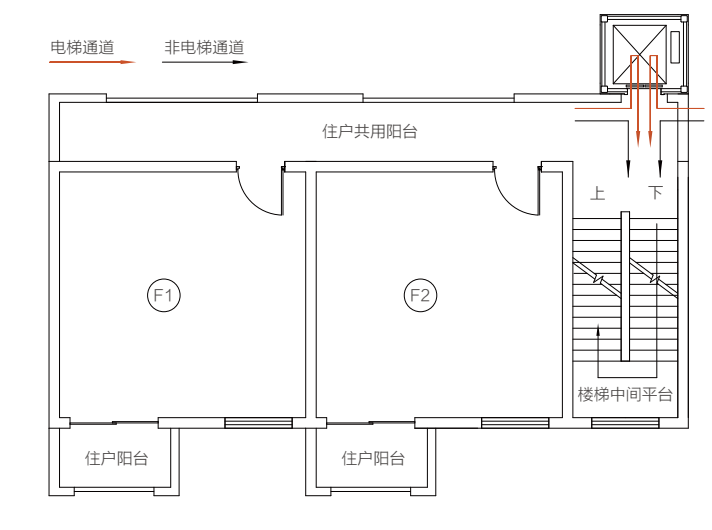

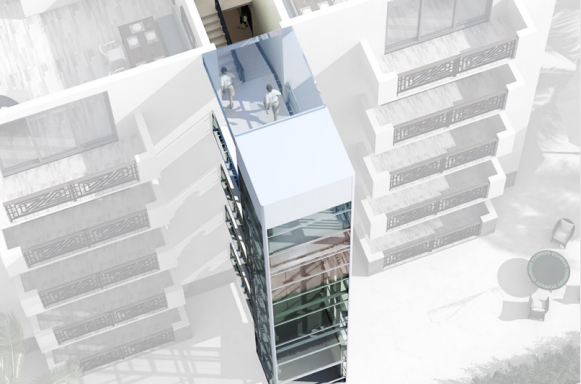

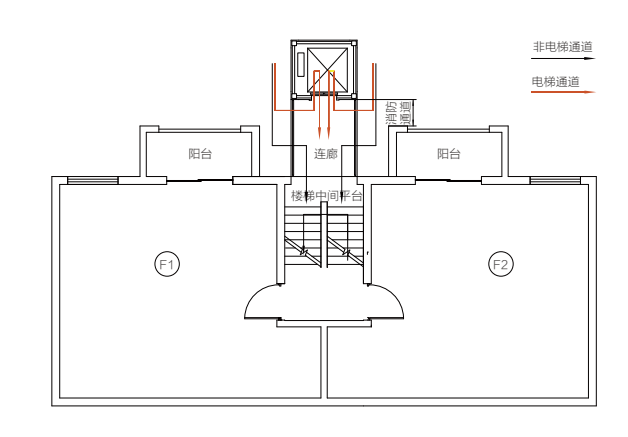

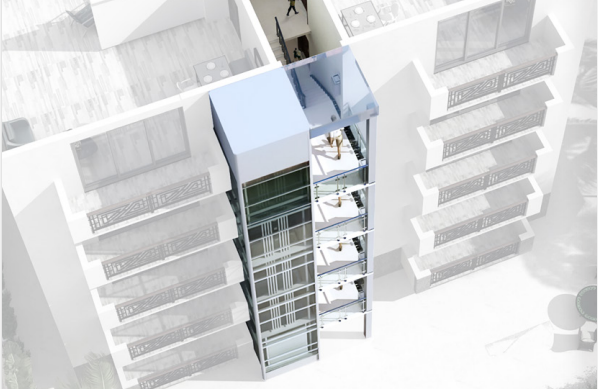

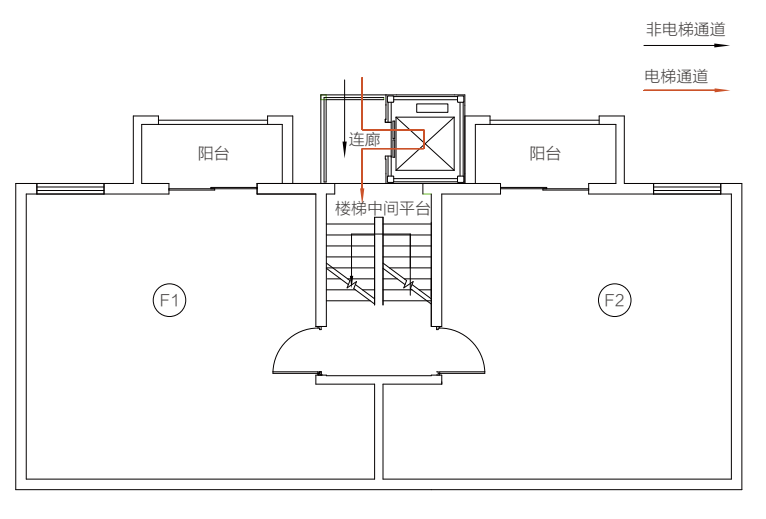

ELEVATOR RETROFITTING SCHEME

Flat floor entry One

Flat Floor EntryTwo

Half-floor entry One

Half-floor entry Two

RETROFITTING CASE

ON-SITE CONSTRUCTION

-

On-site installation progress

-

Day 1-2

Construction preparation, start-up declaration

-

3rd day

Elevator entry & unpacking inspection

-

Days 4-9

hoistway mechanical parts installation

-

Days 10-13

Computer room equipment installation

-

Days 14-16

Electrical wiring and supporting construction of civil works

-

Days 17-19

Commissioning and factory inspection

-

Days 20-21

Acceptance and Handover

400-611-0202

400-611-0202

Message

Message  WhatsApp

WhatsApp